Slab cracks, caused by factors like differential settling and structural deficiencies, require careful assessment for effective Crack Repair. Identifying crack types (diagonal, vertical, horizontal) guides selection of methods, from epoxy filling for minor cracks to structural stabilization for severe cases. Thorough damage assessments, using techniques like moisture testing, ensure comprehensive repairs. Using specific tools and high-quality materials, experts implement customized solutions, preparing slabs properly and addressing root causes to prevent future cracking. Regular maintenance, including prompt crack repair and suitable product choice, extends slab lifespan in diverse conditions.

Slab restoration is a crucial process for maintaining structural integrity and aesthetics in buildings. This article delves into the comprehensive guide on crack repair, addressing various aspects from understanding slab cracks, their causes, and types, to assessment methods for identifying damage extent. We explore different crack repair techniques, essential tools, step-by-step restoration processes, common mistakes to avoid, and maintenance tips for long-lasting results, focusing on effective crack repair solutions.

Understanding Slab Cracks: Causes and Types

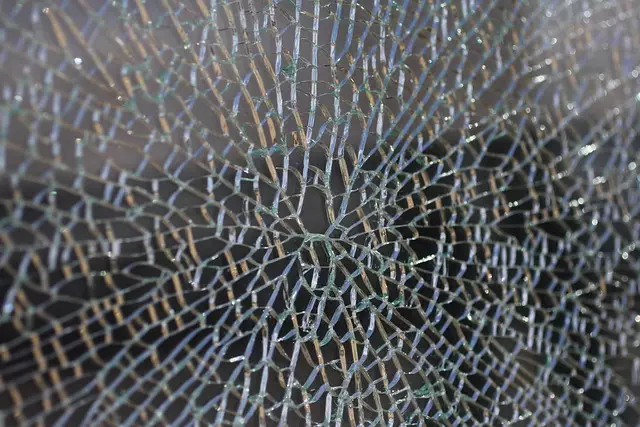

Slab cracks can be a common concern for many property owners, especially in older structures or areas with shifting soil conditions. Understanding the causes and types of these cracks is essential when considering slab repair methods. There are several factors that contribute to the formation of cracks in concrete slabs, including structural issues, environmental changes, and poor initial construction.

One of the primary causes is differential settling, where different parts of the slab cure at varying rates due to inconsistent moisture levels or temperature variations, leading to stress buildup and eventual cracking. Another common reason is heave and settlement caused by fluctuations in soil moisture content, particularly in regions with high humidity or water tables. Additionally, cracks can result from structural deficiencies, such as inadequate reinforcement or design flaws, which may not be immediately apparent without professional evaluation. Identifying the specific type of crack—like diagonal, vertical, or horizontal—is crucial for selecting the most effective crack repair method.

Assessment: Identifying Damage Extent

Assessing the extent of damage is a crucial step in slab restoration, especially for crack repair. This initial evaluation involves meticulous inspection to identify the severity and type of cracks present. The process begins with a visual examination, where professionals look for surface-level cracks, which can range from hairline fractures to broader gaps. These visible defects are often an indicator of deeper structural issues.

During assessment, experts may also employ advanced techniques like moisture testing and load-bearing analysis to gain a comprehensive understanding of the slab’s condition. Moisture content in slabs can contribute to cracking, so identifying its source is vital for effective crack repair. This careful analysis ensures that the restoration process addresses not just the visible cracks but also any underlying problems, guaranteeing a sturdy and aesthetically pleasing result.

Crack Repair Techniques: A Comprehensive Overview

Crack repair is a critical aspect of slab restoration, ensuring structural integrity and aesthetic appeal. The techniques employed can vary greatly depending on the type and severity of cracks. For small, hairline fractures, a simple filling and sealing with appropriate epoxy resins or polyurethane foams may be sufficient. This method not only fills the crack but also hardens to create a strong bond, preventing further expansion.

For wider cracks, especially those showing signs of movement or instability, more advanced techniques are required. These often involve structural stabilization using anchors, braces, or carbon fiber reinforcement sheets. In some cases, partial replacement of the damaged slab section might be necessary. Experts in crack repair thoroughly evaluate the damage, choose suitable materials, and implement tailored solutions to ensure the longevity and safety of the restored surface.

Materials and Tools for Effective Restoration

Restoring slabs, whether concrete or stone, requires the right materials and tools to achieve optimal results. For crack repair, a good starting point is a high-quality epoxy resin specifically designed for slab restoration. This material can fill and strengthen cracks, providing a durable solution that prevents further damage. When selecting an epoxy, consider factors like viscosity, curing time, and color to match the existing slab.

Essential tools for effective crack repair include specialized injection guns or pumps, mixing containers, and various nozzles. These tools facilitate precise application of the epoxy resin into the cracks, ensuring thorough penetration. Additionally, safety gear such as gloves, goggles, and protective clothing is crucial to prevent skin irritation or other hazards associated with chemicals. Proper ventilation is also important during the restoration process to ensure a safe working environment.

Step-by-Step Guide to Slab Crack Repair

Crack repair on slabs is a common task for homeowners and professionals alike. Here’s a step-by-step guide to ensure a successful fix. Begin by assessing the crack’s severity, depth, and width. Minor cracks less than 1/4-inch wide can often be left alone, as they may heal themselves with time. For wider or deeper cracks, preparation is key. Clear the area of debris and ensure the slab is clean and dry before proceeding.

Next, mix a suitable epoxy or polyurethane crack filler according to the manufacturer’s instructions. Use a putty knife to apply the filler to the crack, filling it completely and ensuring there are no air bubbles. Once applied, gently smooth the surface with a wet sponge to blend it with the surrounding slab. Allow the filler to cure fully before walking on or using the area to prevent early damage or loss of adhesion.

Common Mistakes to Avoid During the Restoration Process

During the slab restoration process, avoid common pitfalls that can compromise the integrity and longevity of your structure. One of the most frequent mistakes is neglecting proper preparation before beginning any repair work. This includes not cleaning the surface thoroughly to remove dirt, grease, or existing sealers, which can prevent new materials from adhering correctly. Additionally, using subpar materials for crack repair can lead to further damage down the line, so it’s crucial to invest in high-quality products specifically designed for concrete restoration.

Another error to steer clear of is attempting to fix cracks without addressing their root cause. Simply patching over cracks without understanding why they formed in the first place could provide temporary relief but won’t stop them from reappearing. Always inspect the surrounding area and consider factors like settlement, moisture intrusion, or structural shifts that might be contributing to crack development, ensuring a more permanent solution.

Maintenance Tips for Long-Lasting Results

Regular maintenance is key to ensuring your slab remains in top condition and extends its lifespan. One of the most important aspects is addressing any cracks promptly. Cracks, even small ones, can indicate underlying issues and expand over time if left untreated. Regular inspection is crucial, especially in areas prone to extreme weather changes or heavy foot traffic.

When a crack is noticed, don’t delay. Promptly repair it using suitable methods like filling, sealing, or resurfacing. Using the right products for crack repair is essential; choose those designed specifically for concrete or stone to achieve long-lasting results. Additionally, maintaining proper hydration levels and regularly cleaning the slab can prevent dirt accumulation in cracks, ensuring your restoration work stays effective for longer.